UCHIDASHI

UCHIDASHI

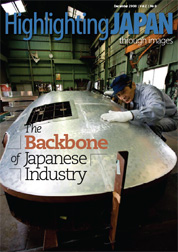

Yamashita Kogyosho is recognised as the pioneer of Shinkansen face production by "Uchidashi", and is a Special Prize recipient of the Monodzukuri Nippon Grand Award. This hand-hammering craftsmanship has contributed greatly to the production of an elegant streamline “face” of the Shinkansen.

The Monodzukuri Nippon Grand Award

Kiyoto Yamashita, the founder (recipient of the Order of the Rising Sun, Gold and Silver Rays), was a self-employed "Uchidashi" craftsman working at Hitachi Kasado Works. He led a team of craftsmen to produce the face of the first Shinkansen test car that was completed in 1962 (March 1963, the test car recorded 256 km/h, the high speed world record at that time).

Kiyoto Yamashita, the founder (recipient of the Order of the Rising Sun, Gold and Silver Rays), was a self-employed "Uchidashi" craftsman working at Hitachi Kasado Works. He led a team of craftsmen to produce the face of the first Shinkansen test car that was completed in 1962 (March 1963, the test car recorded 256 km/h, the high speed world record at that time).

In September 1963, almost one year before the launch of Shinkansen services, Yamashita Kogyosho was founded as supplier for Hitachi to produce Shinkansen faces. Since then, the company has supplied faces of almost all major series of Shinkansen including the latest E5, E6 and E7 series of JR East.

Also faces of intercity express trains, monorail cars and magnetic levitation test cars in Japan have been produced by the craftsmen team. In addition to the face, the company has been supplying various types of streamline shaped train parts for use at driver's cabin and multi-purpose room.

SEIMITSU

SEIMITSU

In 1984, based on experience of train parts production, especially of the train driver’s desks, Yamashita Kogyosho started production of sheet metal precision parts for Hitachi and its group companies.

In the last 30 years, the production of precision parts, "Seimitsu" parts in Japanese, has grown in accordance with the business expansion of the current Hitachi High-Technologies. Nearly half of current sales of Yamashita Kogyosho have been generated from the "Seimitsu" parts production for Hitachi's semiconductor manufacturing equipment for Intel and TSMC.

Yamashita Kogyosho is recognised by METI as one of the Japan's 300 Exciting Monozukuri (Manufacturing) SMEs. The current biggest shareholder is SBIC West Japan, which is one of the first venture capital firms in Japan. The company is situated in the city of Kudamatsu in Yamaguchi-Prefecture, which is the most western part of the Japanese main Island (approx. 1,000 kilometers west of Tokyo).

Yamashita Kogyosho is recognised by METI as one of the Japan's 300 Exciting Monozukuri (Manufacturing) SMEs. The current biggest shareholder is SBIC West Japan, which is one of the first venture capital firms in Japan. The company is situated in the city of Kudamatsu in Yamaguchi-Prefecture, which is the most western part of the Japanese main Island (approx. 1,000 kilometers west of Tokyo).

For more information, please contact us via email info@odeko.co.jp.

Kiyoto Yamashita, the founder (recipient of the Order of the Rising Sun, Gold and Silver Rays), was a self-employed "Uchidashi" craftsman working at Hitachi Kasado Works. He led a team of craftsmen to produce the face of the first Shinkansen test car that was completed in 1962 (March 1963, the test car recorded 256 km/h, the high speed world record at that time).

Kiyoto Yamashita, the founder (recipient of the Order of the Rising Sun, Gold and Silver Rays), was a self-employed "Uchidashi" craftsman working at Hitachi Kasado Works. He led a team of craftsmen to produce the face of the first Shinkansen test car that was completed in 1962 (March 1963, the test car recorded 256 km/h, the high speed world record at that time).

Yamashita Kogyosho is recognised by METI as one of the Japan's 300 Exciting Monozukuri (Manufacturing) SMEs. The current biggest shareholder is SBIC West Japan, which is one of the first venture capital firms in Japan. The company is situated in the city of Kudamatsu in Yamaguchi-Prefecture, which is the most western part of the Japanese main Island (approx. 1,000 kilometers west of Tokyo).

Yamashita Kogyosho is recognised by METI as one of the Japan's 300 Exciting Monozukuri (Manufacturing) SMEs. The current biggest shareholder is SBIC West Japan, which is one of the first venture capital firms in Japan. The company is situated in the city of Kudamatsu in Yamaguchi-Prefecture, which is the most western part of the Japanese main Island (approx. 1,000 kilometers west of Tokyo).